29/09/2021

In recent times we have found many clients who suffer from ignorance of a practice as new as self-consumption, not because it is in itself far from it, but because of the rapid way in which it has grown. In addition, the drop in installation costs in recent years, taking into account the problem of containers from China delay given the situation of the COVID pandemic is still latent.

With the drop in costs, the number of installers has grown and, therefore, offers are piling up on the tables of customers who do not know what decision to make or what criteria to make when choosing. At Àliter Group we have more than 20 years of experience in the market and we want to help you choose your best option and make your experience with self-consumption as rewarding and profitable as possible.

Today we are going to focus on the choice of your solar panels, a fundamental element to build a photovoltaic plant. For this article we have based ourselves on the study carried out each year by

PVEL / DNV, an independent and prestigious laboratory in the field of the solar industry.

In this study, and according to its researchers, the use of lower standards in component materials and insufficient quality controls as the industry expands should be considered as the major cause of newer solar energy projects having lower performance than a few years ago.

A recent study of Europe's first grid-connected solar project, the TISO-10-kW plant in Switzerland, demonstrates the profound impact of material selection on long-term field performance. The use of quality materials in some modules resulted in 20% more energy production after 35 years of field operation.

The researchers determined that the use of different encapsulant formulations was the main cause of the degradation rate. While modules with one type of encapsulant degraded only 4.9% on average after 35 years, modules with two other encapsulant formulations exhibited much higher average degradation rates of 19.1% and 26.1%.

PVEL carries out each year, and since 2014, its PQP Product Qualification Program study. Here are some of the premises by which this study is governed:

- Thermal Cycling Overview: As fielded module temperatures rise and fall, the components expand and contract. With different thermal expansion coefficients, components can expand and contract at different rates in the same environmental conditions. This stresses the bonds between each PV module layer. Solder bond fatigue, for example, increases voltage drop in the module as current passes through a higher-resistance internal circuit, thus diminishing performance when the sun is at its brightest.

- Damp Heat Overview: PV modules experience periods of high temperature and humidity not only in tropical and subtropical regions but also in moderate climates. In these conditions, inferior quality components or substandard lamination procedures can lead to degradation or premature failure. The damp heat test replicates degradation and failure mechanisms that can occur in the field.

- Mechanical Stress Sequence Overview: Excessive thermal and mechanical stress can cause microcracks to form in PV cells. Stress can occur during: cell soldering, lamination, and other module manufacturing processes; exposure to temperature fluctuations, wind, snow, hail, and other environmental conditions; and/or physical damage in transportation, installation, or maintenance. If cracks restrict the flow of current through the cell, modules can produce less energy. They can also form hotspots, introducing safety risks.

- PID (Potential - Induced Degradation): PID can occur within weeks or even days of commissioning. It generally occurs when the internal PV electrical circuit is biased negatively in relation to ground. The voltage between the frame and the cells can cause sodium ions from the glass to drift toward the cell surface, which typically has a silicon nitride (SiN) anti-reflective coating. If pinholes, also known as shunts, in this coating are large enough to allow sodium ions to enter the cell, then performance can be irreparably impaired. Additionally, this voltage can cause a buildup of static charge, which can also reduce performance, although this effect is typically reversible.

- LID + LETID: LID generally refers to the rapid power loss caused by unstable boron-oxygen compounds that occurs when p-type crystalline modules are first exposed to sunlight. Al-BSF module manufacturers historically guaranteed 3% year-one degradation for monocrystalline modules and 2.5% for multicrystalline modules. The outlook for modern PERC and PERT cells is much less clear. They are treated before module manufacturing, leading to historically low LID, but these treatments can increase LETID susceptibility. LETID affects advanced multicrystalline and monocrystalline cell architectures. It has been shown to materialize when cells reach temperatures over 40°C while operating, which not only occurs in hot environments but also in temperate regions during high irradiance. Degradation eventually stabilizes and can recover over time, but regeneration rates vary.

- PAN Performance Overview: In PVsyst, an industry standard modeling program for predicting PV project performance, PAN files model irradiance- and temperature-dependent behavior of PV modules. Module datasheet specifications can be used to generate a functional PAN file but may not define all module performance parameters sufficiently for the full range of potential irradiance and temperature conditions. PVEL measures these conditions in the lab to provide more accurate modelling inputs.

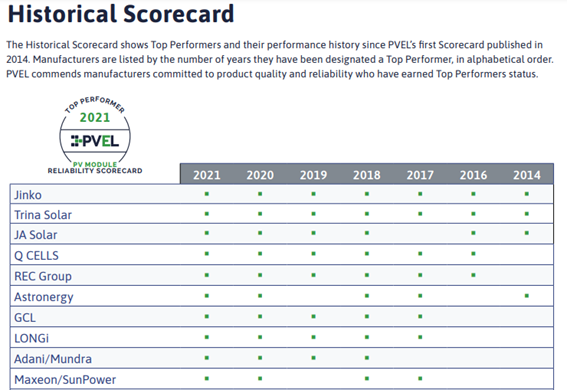

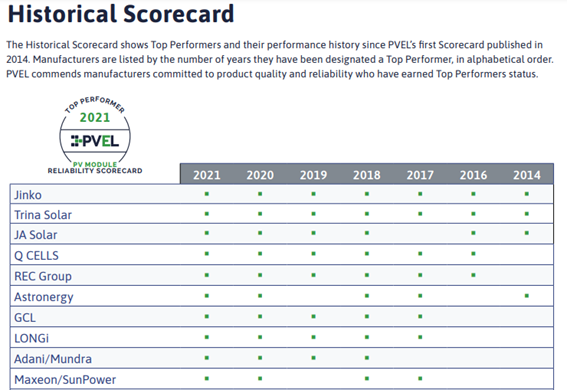

To sum up, the 2021 study shows the following TOP Performers in recent years:

At Àliter Group we use the JA Solar range of solar panels for many of our installed and offered plants. For us, the quality and trust of our clients has been a fundamental premise over the years.

Request your quote now for free or write to us if you have any questions at:

info@alitergroup.com